STER-TACSRTM

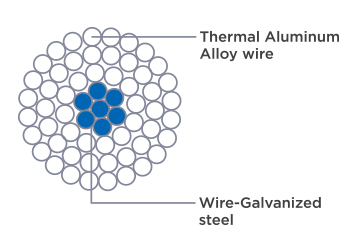

Sterlite® Thermal-resistant Aluminium-alloy Conductor, Steel Reinforced (TACSR) conductors are high ampacity conductors, wherein the inner core is composed of galvanized steel and the outer layers are composed of thermal-resistant aluminium-alloy

APPLICATION

Sterlite® Thermal-resistant Aluminium-alloy Conductor

TACSR conductors are recommended for new lines for high power transfer requirements.

BENEFITS

New aluminium alloys having high thermal resistance can carry 50%-60% more current than ACSR of the same size, while maximum sag and maximum working tension remains almost the same as that of ACSR.

● Can carry 50%-60% more current than ACSR of the same size.

● Higher capacity new lines can be built to deal with future demands.

TECHNICAL SPECIFICATIONS

| PROPERTIES | TACSR (ACSR MOOSE EQUIVALENT) | TACSR (ACSR ZEBRA EQUIVALENT) | TACSR (ACSR PANTHER EQUIVALENT) | |||

| Typical factors | 3.53 mm | 0.1378 in | 3.18 mm | 0.1252 in | 3.00 mm | 0.1181 in |

| Reference specifications | IEC 62004 | IEC 62004 | IEC 62004 | |||

| Total cross section area | 596.99 mm2 | 0.9253 in2 | 484.25 mm2 | 0.7506 in2 | 261.50 mm2 | 0.4054 in2 |

| Conductive wire | Al Zr AT1 | Al Zr AT1 | Al Zr AT1 | |||

| Core wire | Galvanized Steel | Galvanized Steel | Galvanized Steel | |||

| Conductor diameter | 31.77 mm | 1.2508 in | 28.62 mm | 1.1268 in | 21.00 mm | 0.8268 in |

| Weight | 2004 kg/gm | 1346.6 lbs/mile | 1621 kg/km | 1089.3 lbs/mile | 972 kg/km | 653.2 lbs/mile |

| Ultimate tensile strength | 16438 kg | 36239.54 lbs | 14407 kg | 31761.96 lbs | 10119 kg | 22308.55 lbs |

| DC resistance at 20°C temperature | 0.06 Ω/km | 0.09 Ω/mile | 0.07 Ω/km | 0.11 Ω/mile | 0.14 Ω/km | 0.22 Ω/mile |

| Maximum operating temperature | 150°C | 302°F | 150°C | 302°F | 150°C | 302°F |

| Current carrying capacity at maximum operating temperature | 1509 Amp | 1302 Amp | 831 Amp | |||

Assumptions: Ampacity is calculated based on, 45°C (113°F) ambient temperature, 0.6 m/s wind velocity, 0.5 as coefficient of solar absorption, 0.6 as coefficient of emmisivity and 1200 wt/sqm coefficient for solar radiation, at sea level.

Please wait...

Please wait...